Oil filtration systems with just one goal in mind: perfectly clean oil.

It's an absolute necessity for any industry, because an oil film has to guarantee the perfect lubrication of hydraulic machinery and gearboxes. But perfect lubrication requires 100% clean oil. Unfortunately more than 70% of all hydraulic machinery are highly contaminated (>NAS 9, >ISO 21/18/16). Here you can learn how to improve oil cleanliness and how to choose for effective oil filtration equipment. It's easy because...

Bypass Oil Cleaners to effectively remove all contaminants:

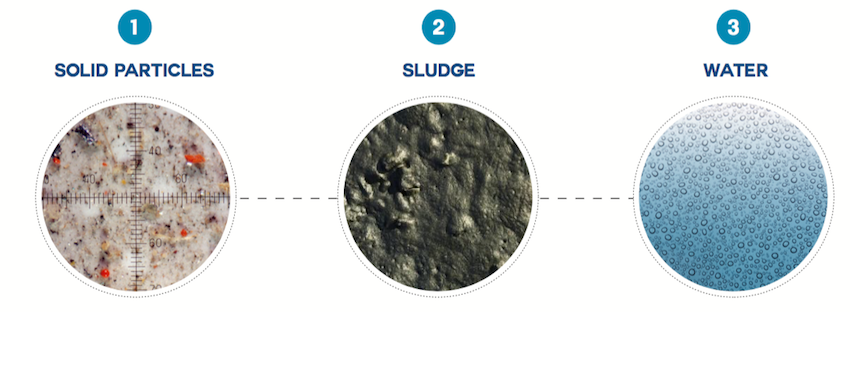

The result is a perfectly clean oil thanks to 3-in-1 oil purification.

Removal of up to 99% of all solid contaminants.

Removal of up to 99% of all solid contaminants.

Elimination of damaging sludge, varnish and oxidation byproducts

Elimination of damaging sludge, varnish and oxidation byproducts

Reduction of water and moisture to less than 100 PPM.

Reduction of water and moisture to less than 100 PPM.

Learn all about...

SOLID PARTICLES

Solid particles multiply continuously in hydraulic systems.

These particles flow through the hydraulic system under high pressure and at high speed and sandblast its components (pumps, valves, seals and cylinders).

more..

These particles flow through the hydraulic system under high pressure and at high speed and sandblast its components (pumps, valves, seals and cylinders).

more..

WATER

Constant changes in oil temperature cause condensation.

The effect of water on oxidation in the oil, however, is dramatic, especially in presence of catalysts like copper (CU) or iron (FE).

more..

The effect of water on oxidation in the oil, however, is dramatic, especially in presence of catalysts like copper (CU) or iron (FE).

more..

SLUDGE & VARNISH

The two most general classifications of insoluble contaminants are hard contaminants, such as dirt, debris and wear particles, and soft contaminants, composed of the various oil degradation by-products.

more..

more..

Bypass Oil Cleaning

Triple R bypass oil cleaners remove particles down to 2 micron, but also remove water and oxidation residues.

Guaranteed clean

Triple R does not sell "micron ratings", we sell the guarantee for "perfectly cleaned oil". No cure? No pay!