Why use Triple R Oil Cleaners?

No more oil changes!

Extend oil life up to 50.000 hrs

No wear, no breakdown!

Eliminate valve & pump failure.

Extend full-flow filter life!

Discharge the load on full-flow filters.

Avoid breakdowns & standstill!

Well-oiled machines never fail.

Increase machine reliability!

Clean oil keeps your machines running.

Increase machine availability!

Reliable machines produce more.

Increase production output!

No standstill means more production.

Save money!

Clean oil reduces maintenance costs

Total oil management

At TRIPLE R we have all the tools for TOTAL OIL MANAGEMENT.

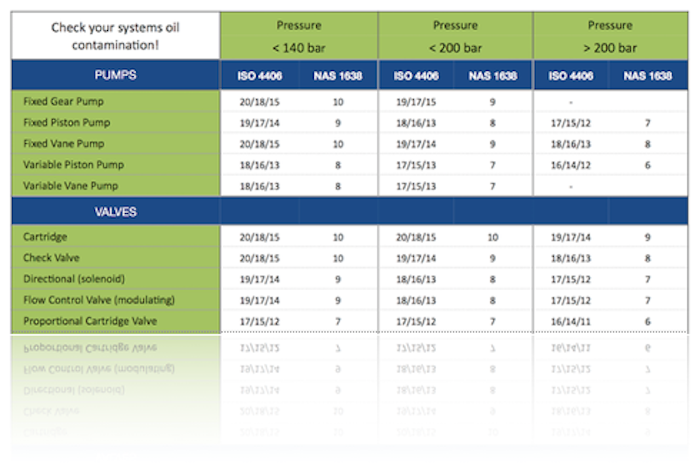

Use the ISO cleanliness codes to set the target alarms for your own machinery cleanliness levels.

Every system requires a certain level of cleanliness. The degree of cleanliness greatly depends on the type of components installed on your machinery.

We recommend to check what type of components you have and to set your oil cleanliness targets accordingly. Download the file below to compare your oil cleanliness target with the level of oil cleanliness that you have in your systems today.

Remember: new, fresh oil isn't clean. It's often too contaminated to run on machinery, like for test stands or hydraulic systems steered by servo-valves.